Architectural Description of American Seating Company Factory Complex - 2003

by Rebecca Smith Hoffman, PastPerfect

Ninth Street divides the American Seating factory complex into two separate, roughly rectangular city blocks. The more northerly block contains a complex of buildings dating from 1888 to 1978, the result of several major building campaigns – in 1888-1889, 1908-1909, 1927-1928, and 1956, with numerous smaller accretions added at various times. The original 1888-1889 building along the south edge at the east end of the block and the 1956 building along much of the north edge of the block are sited with their long axes in an east-west direction in the east two-third of the block. Some early additions, having been encompassed by later additions, no longer exist as individual buildings and are not treated as such here.

Grand Rapids School Furniture Company

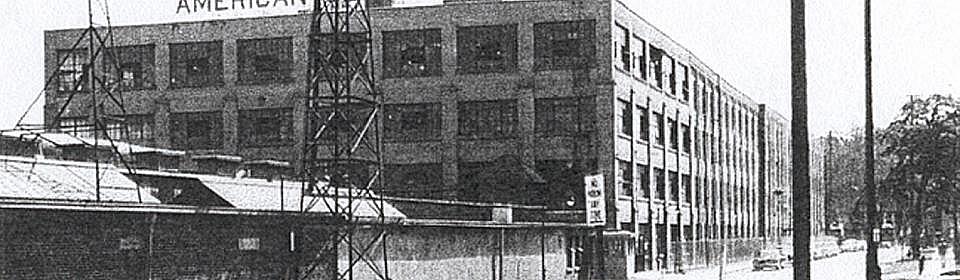

The original four-story cream brick factory (1888 and 1889) extends west nearly 450 feet from Broadway Avenue NW along Ninth Street NW (vacated) in rhythmic bays defined by brick piers rising to the parapet wall; each bay contains two segmental arch-head windows per floor. When viewed from the southeast, this building fills the horizon. Window sash patterns are variously one-over-one, two-over-two or twelve-over-twelve. Rows of corbelling above the fourth floor windows provide the only decoration. The Broadway Avenue (east) elevation is three bays wide; the central bay has segmental arch-head windows, while the outside bays have square-head windows. An L-shaped section of the building extends to the north, forming what once was an open-ended courtyard that has been filled in by a one-story addition. Along the east side of this section is a one-story enclosed loading dock (1960). A massive elevator/water tower stands where the L-shaped section meets the main building. In 1937, the two towers that originally rose from the corners of the building at the main elevation on Broadway Avenue were removed. The first floor of the Broadway Avenue elevation was bricked over circa 1982 and a new entrance to the executive offices was added at the south side. The interior space of the building is variously divided into offices or is open space showing its post and beam construction. Facing Ninth Street NW (vacated) at the west end of the 1888 building is a four-story reinforced concrete addition (Hauser Owen Ames, 1919) with large steel multi-paned windows.

As noted above, numerous interconnected buildings extended the original plant over the years. The visible additions are as follows: Moving north along Broadway Avenue NW is a two-story, flat-roofed concrete block addition (1908) used for packing and shipping with a loading dock along its south side. At the Broadway Avenue (east) elevation, its square window openings have twelve-pane fixed metal sash. The entire second floor and all but six of the first floor windows have been covered over; those windows left uncovered have been painted on the interior surface. The next addition to the north is a one-story brick, flat-roofed steel plant (1910), where steel furniture parts were fabricated; each of its five bays, defined by concrete-capped piers, contains a large multi-paned steel sash window with pivot vent, the top of which has been covered over and the bottom painted on the interior surface. The steel plant was enlarged to the north by an Osgood & Osgood-designed one-story, flat-roofed addition (1938), with a long, narrow glass block window (covered over) set high in its smooth brick wall. Another large one-story expansion (1956), designed by Giffels & Vallet, Inc., L. Rossetti of Detroit, sets at the corner of Broadway Avenue and Eleventh Street. Stretching over 500 feet along Eleventh Street west from Broadway Avenue, it is the largest structure in footprint area in the complex. The 1956 building’s Broadway Avenue elevation echoes that of the 1938 addition; only a slightly different color brick distinguishes the later building. There is a glass wall entrance facing Eleventh Street NW (covered over above the entrance doors); the top one-third of the building displays multi-paned fixed steel sash (covered over). American Seating constructed this building as part of a general improvement program started in 1951, when the company decided not to move its plant outside the city. It provided much needed manufacturing space to accommodate the enormous growth the company was experiencing by the mid-1950s. Facing Seward Avenue NW is a glass wall manufacturing plant (1927) designed by Smith, Hinchman & Grylls. To the south of this addition, the 1888 foundry building rises above small one-story concrete block additions (1978 and unknown date). The plant additions and the foundry interior spaces are open plan.

The more southerly block contains a massive brick and concrete warehouse, constructed in 1923, sited north to south at the western end of the block. A large brick manufacturing building constructed in 1927 is sited east to west along Seventh Street and is connected to the warehouse at the south end of the east side. A free-standing power house (1923, expanded 1951) is located near the north end of the warehouse along Ninth Street. The soaring concrete smokestack of the power plant and the elevator tower of the manufacturing building are key visual landmarks of the West Side.

The warehouse, designed by Neiler, Rich & Company of Chicago, is a rectangular, four-story, flat-roofed, unpainted red brick structure. The timber-frame building has a concrete base and is twenty-two bays long and two bays wide; each bay is divided by piers that end at the top of the fourth floor windows with a cast concrete cap and cross detail. The large steel, multi-paned windows contained within the bays have center-pivot vents and concrete sills. Three corners of the building are defined by bastion-like structures, the curved rooflines of which rise above the parapet wall. There is cast concrete detailing above and beside the fourth floor windows. A primary architectural feature is the elevator and stair tower that rises six stories at the southeast corner, with round arch-head windows at the top story, which also features simple concrete detailing. A concrete stringcourse at the second floor line divides the first floor from the upper floors around the parameter of the building; a second concrete stringcourse wraps around the north and south ends of the building, beginning and ending at the first window bay of each elevation and running along the top of the first floor windows. A roofed wood and concrete platform along the length of the west elevation once facilitated loading and unloading the cars that ran on the rail spur that was located there. A truck loading dock (1942) is located at the east elevation near where it joins with the manufacturing addition. The interior has wood floors, square section wood columns, brick walls, and ceilings open to the joists.

Neiler, Rich & Company also designed the brick power plant, which rises one story from a concrete raised basement; its 184-foot concrete smokestack has been reduced in height by about ten feet. Like the warehouse, it has simple concrete trim and steel, multi-paned windows. This plant, described in the August 1923 issue of the company magazine, The Seater, as "an example in economy—a lesson in thrift,” was powered by coal, as well as by wood waste and sawdust, which were blown to it from the Wood Plant. Exhaust steam was used for the generation of power, rather than being allowed to dissipate into the air. The boilers supplied heat for the buildings in winter and high pressure superheated steam to power factory operations. The new power plant made possible the elimination of the belt drive and the institution of the motor drive for machines used in the manufacturing process. A 100 x 75 foot spray pond capable of condensing 20,000 pounds of steam per hour was located south of the power plant and east of the warehouse. It was covered over in the mid-1950s. By 1950, the capacity of the power plant was unable to meet the company’s ever-expanding production needs. The north wall was razed and the building extended to Ninth Street (Owen, Ames, Kimball Construction Company) to accommodate new boilers, which doubled the plant’s steam capacity. This expansion can be distinguished from the original building by its lack of detailing.

In 1927, the massive Smith, Hinchman & Grylls-designed manufacturing building was completed. Attached to the warehouse at the south end of the east side of the building, it stretches east more than 450 feet along Seventh Street NW. Designed to complement the warehouse, it is a rectangular, four-story, flat-roofed, reinforced concrete building with flat slab floor structure and face brick at the south and east elevations. On the south elevation fourteen bays are defined by brick piers rising from the concrete stringcourse at the second floor line to the concrete capped parapet. The rhythm of the bays is broken near the east and west ends by a three bay wide stair and elevator tower projecting one bay from the plane of the building. The towers, which rise above the parapet wall, contain large freight elevators. The two large steel, multi-pane windows contained within each bay have center-pivot vents and concrete sills. At the first floor are massive segmental arch-head steel, multi-pane windows capped with a double row of voissoirs. A metal and glass entrance was added at the northeast corner (c. 1980s). The north elevation has large steel, multi-pane windows in bays separated by slim reinforced concrete piers. The installation of brick veneer was not completed on the remainder of this elevation. The interior space is open with round concrete mushroom columns and flat concrete slab ceilings, wood floors, and painted brick walls. A one-story, flat-roofed section of this building extends to the north; it has massive steel, multi-pane windows separated by slim reinforced concrete piers. The interior open space rises to a height of twenty-one feet with massive round concrete mushroom columns and concrete ceiling, floor, and walls.

The American Seating Company plant today forms two separate parcels. The northerly block, containing the 1888-1889 building and its subsequent expansions, is still owned by American Seating and continues in use, while the southerly block is owned by American Seating Park, LLC.

In 2003, the warehouse was rehabilitated for use as housing; the manufacturing building was rehabilitated for use as American Seating corporate offices on the first floor and housing on the upper floors; and the powerhouse was rehabilitated for commercial use.

facebook

facebook